Thanks to a dynamic partnership with Georgia Tech’s Rural Computer Science Initiative and Georgia AIMS (Artificial Intelligence in Manufacturing, Bainbridge High School is proud to announce the redesign of its Engineering Lab into a state-of-the-art SMART Manufacturing Lab. Launching next year, this innovative space will serve students enrolled in Computer Science, Engineering and Manufacturing CTAE courses, providing them with hands-on experience in advanced manufacturing technologies, applied computer science and modern engineering practices.

A Fresh Face and Powerful Tools for the Future

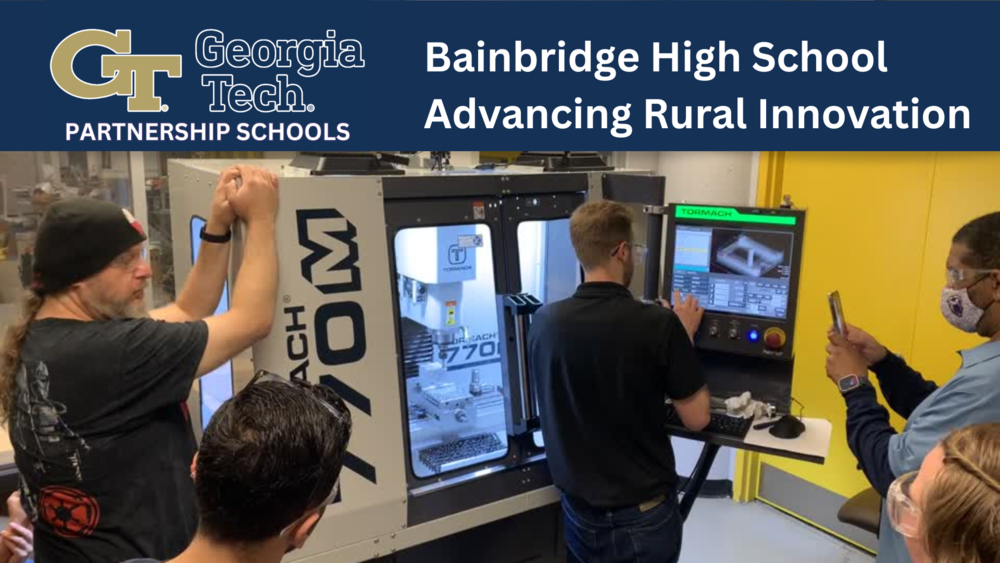

This transformation is backed by significant support from the Southwest Georgia Regional Commission through the Georgia Artificial Intelligence in Manufacturing Economic Development Administration’s Build Back Better Regional Grant Challenge. The Georgia AIM coalition aims to establish the United States as a leader in AI manufacturing while ensuring these systems complement, rather than replace, existing workers. The coalition focussed on accelerating the transition to automation in manufacturing, while diversifying the next generation of AI leadership and the AI manufacturing workforce. Bainbridge High School's Engineering lab’s facelift includes brand-new computers, five Bambu Lab X1C 3D printers, and a powerful Tormach 770 CNC machine. Students will also have access to a racetrack designed to complement their projects and testing activities as they use Smart Manufacturing practices to design and test 3D designed and CNC Machines race cars.

Integration with VEX WorkCell and Python Programming

The SMART Manufacturing Lab will integrate seamlessly with the VEX WorkCell program which is also new to the BHS lab, allowing students to explore industrial robotics and factory automation. Another key feature of the revamped curriculum is the incorporation of Python programming for data collection and analysis, empowering students to make data-driven decisions and modernizing their learning experience. This holistic approach prepares students not just to understand manufacturing equipment, but to harness data and coding skills essential for the workforce of tomorrow.

Empowering Educators, The Bearcat Way

Teachers Jarod Lovering and Mac Lewis recently received hands-on training from Dr. Kyle Saleeby of Georgia Tech on operating the new Tormach 770 CNC machine, ensuring they can expertly guide students in using this advanced technology. As Mr. Lewis shares, “I'm most excited to see what my students will be able to do once they get more hands-on with the new equipment.” This dedication to skill-building reflects the Bearcat way—combining passion, precision, and innovation to empower the next generation.

Special Thanks to Our Partners and Trainers

Decatur County extends heartfelt thanks to Dr. Kyle Saleeby from Georgia Tech for leading the training sessions and to the Georgia Tech Research Institute (GTRI) along with Sean Mulvanity for selecting Decatur County among the three pioneering school systems from Southwest Georgia to pilot this cutting-edge program. (Decatur County Schools, Thomas City Schools, Thomas County Schools.

In the words of Amy Zock, Director of Instructional Technology and STEM, “Our strategic partnership with Georgia Tech, PowerUp EDU, WOZ Ed, and the Georgia AIMS initiative is transforming what’s possible for Decatur County. Together, we’re not just bringing cutting-edge tools and AI-driven content into our classrooms — we’re building a future-ready workforce right here in rural Georgia. These collaborations are opening doors to high-tech careers, empowering our students to lead in tomorrow’s industries, and putting Bainbridge on the map as a hub for innovation and opportunity.”

Engineering, Computer Science and SMART Manufacturing, The Bearcat Way

The new SMART Manufacturing Lab supports a comprehensive Engineering and Manufacturing course developed in partnership with Georgia Tech. The curriculum covers:

Introduction to manufacturing and data analytics

Computer-Aided Design (CAD) using Fusion 360

Python programming basics for data collection and visualization

Smart manufacturing processes including 3D printing and machining

Robotics integration with VEX WorkCell units-focused on automating processes

Hands-on projects like race car design, fabrication, and testing with data-driven iteration

Students will engage in a full engineering design process—from conceptual sketches and predictive modeling to prototyping and performance analysis—building critical skills for STEM careers. "This curriculum sets our students up for success--especially as we launch our (FRC) FIRST Robotics team at BHS this year!" explained Mr Lovering, computer science teacher and FIRST FRC coach and mentor. The FIRST FRC team will build on the existing FIRST FLL Lego Robotics team established last year at Bainbridge Middle School.

About the Georgia Tech Rural Computer Science Initiative

This initiative aims to bridge the technology gap in rural areas by providing high-quality computer science education, workforce development, and access to cutting-edge tools. Through strategic partnerships like ours at Bainbridge High School, GaTECH's Rural Computer Science Initiative supports rural students in gaining the skills and experiences needed to thrive in a rapidly evolving technological landscape. "And there is so much more to come!" commented Zock.

Looking Ahead: FARM BOTS and Wearable Athletic Sensors

The SMART Manufacturing Lab is just the beginning. Coming soon, students will have opportunities to work with innovative technologies such as FARM BOTS—automated agricultural robots—and wearable athletic sensors, expanding their exposure to emerging fields in engineering and data analytics.

Together, we are cultivating the next generation of innovators, engineers, and problem-solvers right here in Decatur County. Stay tuned for more exciting developments!